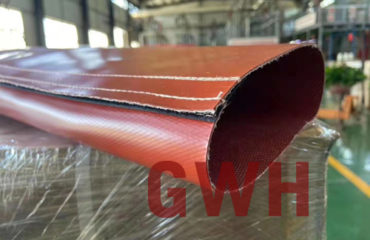

Fire sleeve is a kind of industrial protection products, made of high-quality protection materials, can be used in a harsh environment to protect various pipeline equipment from environmental factors, can be long-term and effective normal operation. So what are the requirements of the fire proof casing installation process? Next, I will introduce it to you- -the next one:

The installation process of fire casing is: installation preparation-sleeve installation-installation test.

1.Installation preparation: Before preparing for installation, we should first understand the relevant knowledge of fire casing, as well as the actual working environment and protection requirements, to ensure that the performance, size and structure of the selected fire casingan meet the installation and use requirements.

2.Bushing installation: when installing fire casing, install it according to the structure of the selected casing. For example: the tube type casing can be directly from the end of the pipeline into the buckle casing can be broken off directly wrapped to the pipeline after the sticky tape, winding casing can be directly wrapped around the pipeline.

3.Installation and testing: After the installation is completed, attention should be paid to check whether the installation is qualified, to ensure that after the installation is qualified, it can be used normally to play a good protection effect. Fire casing is used in a wide range, fire insulation effect is better, but want to play its effect, not only the installation steps need to pay special attention to, the product quality itself should pay special attention to-under.